**EDIT** Question about head bolt tool

#22

Originally Posted by RSracer

::Relaxing::

But..

But..

Originally Posted by RSracer

Although why are you bragging about either coal, gas or steam turbine generators on a car forum.

I fly as Captain most of the time in a 3 person crew. Operating turbine powered aircraft and troubleshooting is what I am trained to do. We are required to have a comprehensive understanding of all aircraft systems which we operate. Before turbine aircraft I was operating piston driven ones. Turbine is definitely better minus the ridiculous initial acquisition costs.

Peace and health in the New Year to you guys!

#23

Back to one of the topics at hand.

Balance Shafts. I have heard and personally know people who have pulled them out of the 2AZ-FE and saw their journal bearings were destroyed cause the motor harm.

If anyone knows of a 2AZ-FE being destroyed from lack of balance shafts let me know. If you know what might go first from deleting these I'd like to know.

Everyone has much to learn, especially us young guys, I am no exception!

I love learning... Please feed my brain!

Balance Shafts. I have heard and personally know people who have pulled them out of the 2AZ-FE and saw their journal bearings were destroyed cause the motor harm.

If anyone knows of a 2AZ-FE being destroyed from lack of balance shafts let me know. If you know what might go first from deleting these I'd like to know.

Everyone has much to learn, especially us young guys, I am no exception!

I love learning... Please feed my brain!

#24

Rs Racer you are new to engines arent you I can tell. Are you serious wikipedia hahahahahaha yea thats reliable  .

.

Did you pull your shafts or did you have a shop? The rotating assembly is balanced WITHOUT the "balance shafts" the name Balance shaft is missleading. They don't BALANCE any thing. They are purely for the comfort of the average person wanting to buy this car.

The rotating assembly is balanced WITHOUT the "balance shafts" the name Balance shaft is missleading. They don't BALANCE any thing. They are purely for the comfort of the average person wanting to buy this car.

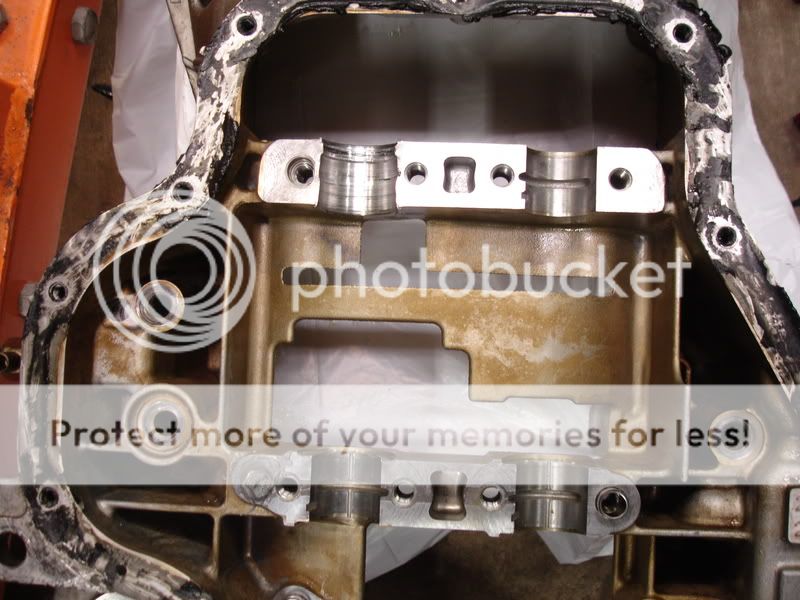

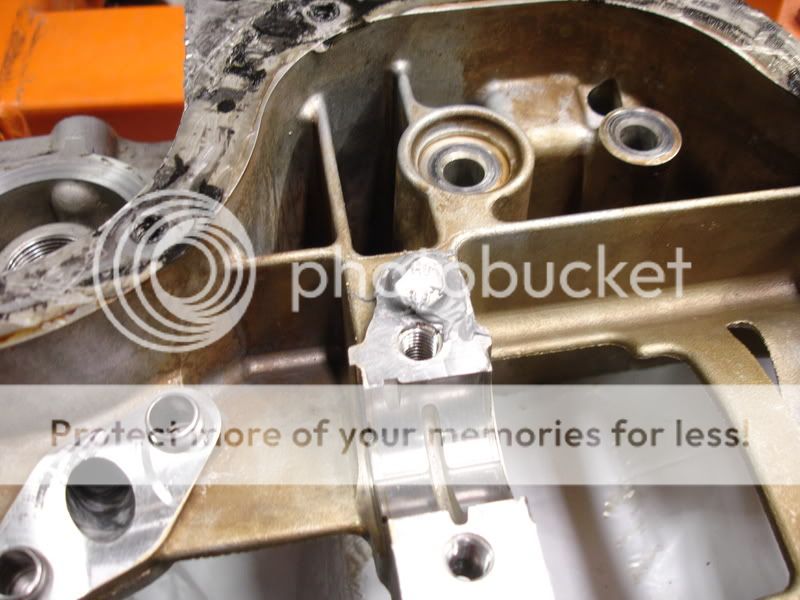

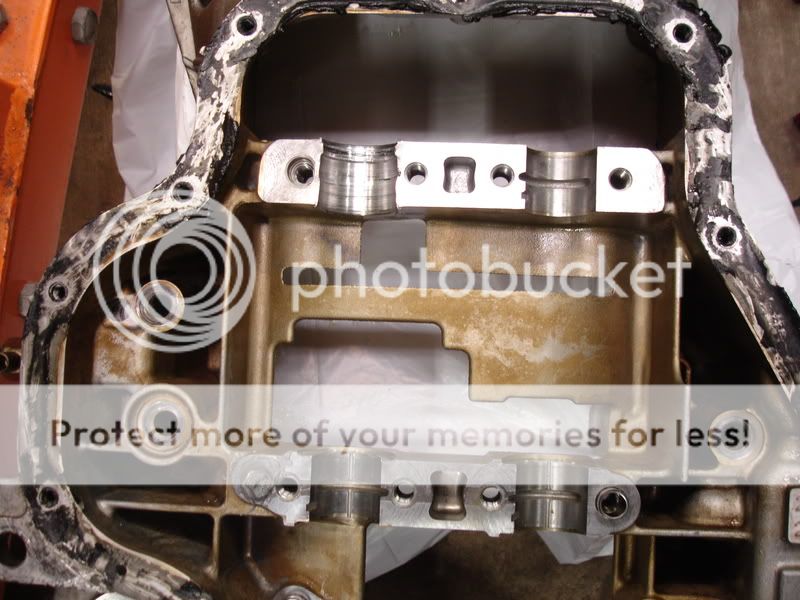

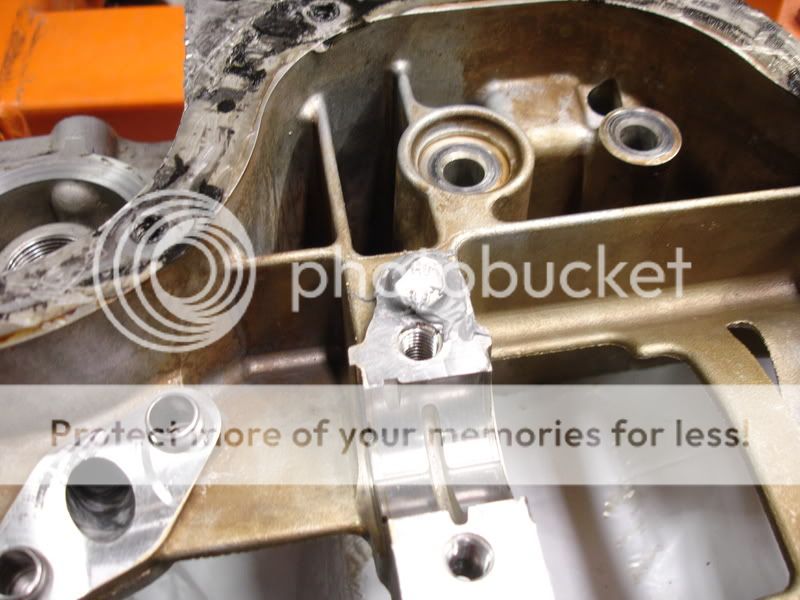

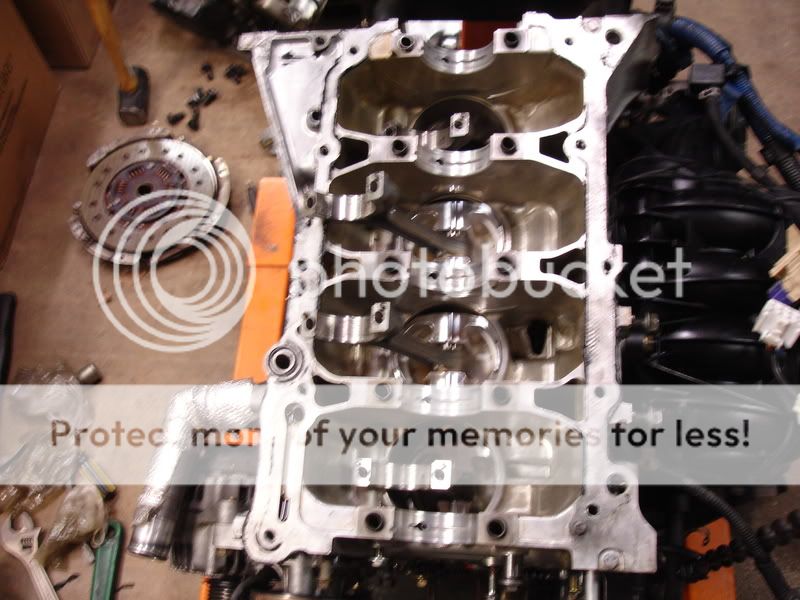

The balance shafts spin TWICE as fast as the rest of the motor. So when your motors idleing at 800 RPM they are spinning at 1600 RPMS. They were never meant to take such great HP and TQ increase. The balance shafts are driven on one side by 4 gears, one on the crank (which you can machine off BUT must have the rotating assembly re balanced), 2 off of the first balance shaft and one on the secondary balance shaft. The problem is that they are on one side of the shaft so what happens when you spin (add more Tq) to 2 shafts at the same end and spinning different directions? One side (the driven side) try and move closer together and the non driven side trys to pull apart. This action puts MORE STRESS on the Bearing in which you CAN'T upgrade to racing bearings. Thus making the stress on the split part of the bearing and pulling the bearing out of its journal. Here are some pics of what happens when you make 400 WHP and 385 WTQ with out pulling the shafts Enjoy!

As Xero said it is normal practice on High Hp Evos and many other cars.

Oh yea b4 you tell me to learn how to change my oil I am the most **** person on all my fluids. I check my oil EVERY GAS FILL UP change any where from 2500 to 3000 miles. I only Use Mobil 1 Extended performance with a Mobil 1 of K&N oil filters.

Also you should def upgrade your oil pump cause the 05 pumps are weak.

Did you pull your shafts or did you have a shop?

The balance shafts spin TWICE as fast as the rest of the motor. So when your motors idleing at 800 RPM they are spinning at 1600 RPMS. They were never meant to take such great HP and TQ increase. The balance shafts are driven on one side by 4 gears, one on the crank (which you can machine off BUT must have the rotating assembly re balanced), 2 off of the first balance shaft and one on the secondary balance shaft. The problem is that they are on one side of the shaft so what happens when you spin (add more Tq) to 2 shafts at the same end and spinning different directions? One side (the driven side) try and move closer together and the non driven side trys to pull apart. This action puts MORE STRESS on the Bearing in which you CAN'T upgrade to racing bearings. Thus making the stress on the split part of the bearing and pulling the bearing out of its journal. Here are some pics of what happens when you make 400 WHP and 385 WTQ with out pulling the shafts Enjoy!

As Xero said it is normal practice on High Hp Evos and many other cars.

Oh yea b4 you tell me to learn how to change my oil I am the most **** person on all my fluids. I check my oil EVERY GAS FILL UP change any where from 2500 to 3000 miles. I only Use Mobil 1 Extended performance with a Mobil 1 of K&N oil filters.

Also you should def upgrade your oil pump cause the 05 pumps are weak.

#25

Haha i managed to do something almost identical to mine with just over 250whp over about a year period  Thats about what my bearing looked like when i got the motor torn down - but my secondary hsaft gear was in much worse shape - ill post my pics tomm when i organize things in the garage :0

Thats about what my bearing looked like when i got the motor torn down - but my secondary hsaft gear was in much worse shape - ill post my pics tomm when i organize things in the garage :0

#29

^^^ Balance shafts KILL MOTORS.

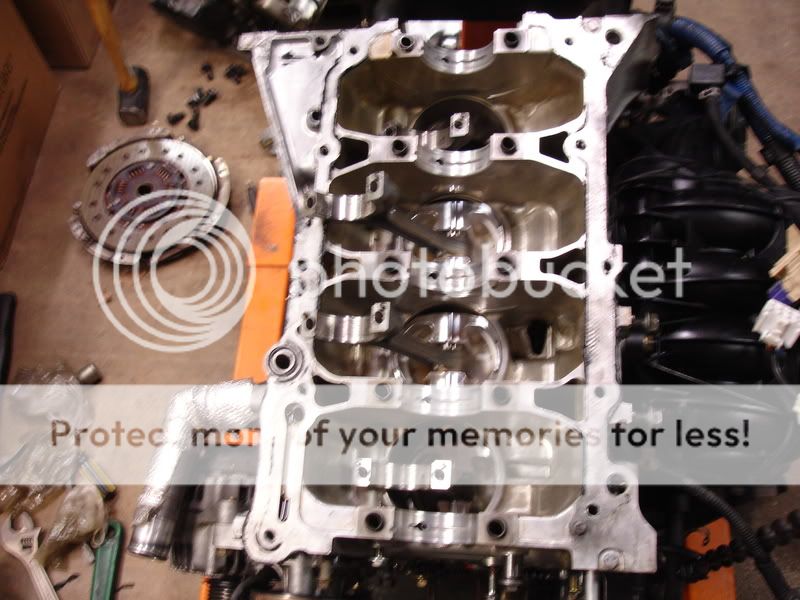

Oh yea see the big gear on the crank that spins the ACCESSORY driven "balance shafts"

^^^^thats the rotating assembly where are the balance shafts oh yea they are part of the crank case stiffiner which is seperate from the rotating assembly.

Look where the balance shafts go and look where the rotating assembly is.

Oh yea see the big gear on the crank that spins the ACCESSORY driven "balance shafts"

^^^^thats the rotating assembly where are the balance shafts oh yea they are part of the crank case stiffiner which is seperate from the rotating assembly.

Look where the balance shafts go and look where the rotating assembly is.

#30

As for the cylinder head here is some in formation for you.

Cylinder Head Set Bolt

Standard bolt length 161.3 to 162.7 mm (6.350 to 6.406 inch)

Maximum bolt length 164.2 mm (6.465 inch)

Cylinder Head Torque and Sequence

NOTICE: The cylinder head bolts are tightened in 2 successive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Using several steps, uniformly install and tighten the 10 cylinder head bolts and plate washers with a bi-hexagon wrench 10 mm in the sequence shown in the illustration.

Torque 78.5 Nm (800 kgf-cm, 58 ft. lbs.)

Mark the front of the cylinder head bolts with paint.

Retighten the cylinder head bolts by 90°in the same sequence as step above.

Cylinder Head Cover Torque

Install the cylinder head cover with the 8 bolts and 2 nuts.

Torque:

Bolt A 11 Nm (112 kgf-cm, 8 ft. lbs.)

Bolt B 14 Nm (143 kgf-cm, 10 ft. lbs.)

Nut 11 Nm (112 kgf-cm, 8 ft. lbs.)

Camshaft Bearing Torque and Sequence

Examine the front marks and numbers and check that the sequence order is as shown in the illustration. Then install the bearing caps onto the cylinder head.

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

Torque:

Bearing Cap No. 2 29.5 Nm (301 kgf-cm, 22 ft. lbs.)

Bearing Cap No. 3 9.0 Nm (92 kgf-cm, 80 inch lbs.)

The tool can be found here for the head bolts.

http://buy1.snapon.com/catalog/item....re&dir=catalog

Cylinder Head Set Bolt

Standard bolt length 161.3 to 162.7 mm (6.350 to 6.406 inch)

Maximum bolt length 164.2 mm (6.465 inch)

Cylinder Head Torque and Sequence

NOTICE: The cylinder head bolts are tightened in 2 successive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Using several steps, uniformly install and tighten the 10 cylinder head bolts and plate washers with a bi-hexagon wrench 10 mm in the sequence shown in the illustration.

Torque 78.5 Nm (800 kgf-cm, 58 ft. lbs.)

Mark the front of the cylinder head bolts with paint.

Retighten the cylinder head bolts by 90°in the same sequence as step above.

Cylinder Head Cover Torque

Install the cylinder head cover with the 8 bolts and 2 nuts.

Torque:

Bolt A 11 Nm (112 kgf-cm, 8 ft. lbs.)

Bolt B 14 Nm (143 kgf-cm, 10 ft. lbs.)

Nut 11 Nm (112 kgf-cm, 8 ft. lbs.)

Camshaft Bearing Torque and Sequence

Examine the front marks and numbers and check that the sequence order is as shown in the illustration. Then install the bearing caps onto the cylinder head.

Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

Torque:

Bearing Cap No. 2 29.5 Nm (301 kgf-cm, 22 ft. lbs.)

Bearing Cap No. 3 9.0 Nm (92 kgf-cm, 80 inch lbs.)

The tool can be found here for the head bolts.

http://buy1.snapon.com/catalog/item....re&dir=catalog

#31

Information about the balance shafts in OUR motors wierd how it doesnt say anything about balancing hmmm wierd and this is from toyota.

Development of Polymer Gear Balance Shaft System for 2AZ-FE Engine.Accession number;01A0151367

Title;Development of Polymer Gear Balance Shaft System for 2AZ-FE Engine.

Author;ISHIKAWA MAKOTO(Toyota Mot. Corp.) NAKAMURA YUKIO(Toyota Mot. Corp.) HORI KOHEI(Toyota Mot. Corp.) KODAMA NORIKAZU(Toyota Mot. Corp.) HOSOI HIROSHI(Toyota Mot. Corp.) HORITA YUJI(Toyota Mot. Corp.)

Journal Title;Toyota Tech Rev

Journal Code:F0431A

ISSN:0916-7501

VOL.50;NO.2;PAGE.52-57(2000)

Figure&Table&Reference;FIG.17, REF.3

Pub. Country;Japan

Language;Japanese

Abstract;The in-line four-cylinder engine, when compared to engines with more cylinders, has numerous advantages, such as lighter weight, lower cost, lower fuel consumption, and compact size, but it also has the disadvantage of large secondary rotational vibration. In recent years, the mounting of a secondary balance shaft has become more common as a means of eliminating this vibration. One objective in the development of the 2AZ-FE engine was the development of a balance shaft with high overall performance, including lower drive noise. A polymer gear, which has never been used until now, was selected for the drive method. The authors succeeded in commercializing this technology for the first time in the world and ensured its reliability by promoting the simultaneous development of new polymer materials and an optimal shock-absorbing mechanism. At the same time, concerted efforts to reduce cost, friction torque, and weight resulted in 50% reductions in these factors in comparison with the conventional 5S-FE engine. (author abst.)

More on the crank balancing.

The forged steel crankshaft is fully balanced with eight counterweights and supported by five main bearings. A helical gear pressed in No. 3 counterweight drives twin contra-rotating balance shafts in the shaft housing within the lower crankcase.

Straight from the Toyota press room!!!

http://www.toyota.com/toyotaSearch/s...afts&locale=en

The 16-valve DOHC engine uses VVT-i. Undersquare, with a bore of 3.48 inches and a stroke of 3.78 inches, it displaces 2,362 cc or 144.1 ci and operates with a 9.8:1 compression ratio to produce 158 hp at 6,000 rpm and 162 lb-ft of torque at 4,000 rpm. Its horsepower and torque curves cross at about 5,200 rpm.

Features include enhanced bore circularity for reduced friction, a block reinforced for additional rigidity, new, lighter-weight pistons and new piston shape, with an optimized skirt for reduced friction. This engine also uses a balance shaft for vibration suppression, and oil jets to help piston cooling.

Finally, this engine's exhaust system is improved to provide lower backpressure for improved output.

The 2.4-liter engine transmits its power through the five-speed manual transmission, but is available with a five-speed automatic. This is an ECT that is light and compact, and that uses a highly efficient torque converter.

Please tell me where it says it balaneces anything?

Development of Polymer Gear Balance Shaft System for 2AZ-FE Engine.Accession number;01A0151367

Title;Development of Polymer Gear Balance Shaft System for 2AZ-FE Engine.

Author;ISHIKAWA MAKOTO(Toyota Mot. Corp.) NAKAMURA YUKIO(Toyota Mot. Corp.) HORI KOHEI(Toyota Mot. Corp.) KODAMA NORIKAZU(Toyota Mot. Corp.) HOSOI HIROSHI(Toyota Mot. Corp.) HORITA YUJI(Toyota Mot. Corp.)

Journal Title;Toyota Tech Rev

Journal Code:F0431A

ISSN:0916-7501

VOL.50;NO.2;PAGE.52-57(2000)

Figure&Table&Reference;FIG.17, REF.3

Pub. Country;Japan

Language;Japanese

Abstract;The in-line four-cylinder engine, when compared to engines with more cylinders, has numerous advantages, such as lighter weight, lower cost, lower fuel consumption, and compact size, but it also has the disadvantage of large secondary rotational vibration. In recent years, the mounting of a secondary balance shaft has become more common as a means of eliminating this vibration. One objective in the development of the 2AZ-FE engine was the development of a balance shaft with high overall performance, including lower drive noise. A polymer gear, which has never been used until now, was selected for the drive method. The authors succeeded in commercializing this technology for the first time in the world and ensured its reliability by promoting the simultaneous development of new polymer materials and an optimal shock-absorbing mechanism. At the same time, concerted efforts to reduce cost, friction torque, and weight resulted in 50% reductions in these factors in comparison with the conventional 5S-FE engine. (author abst.)

More on the crank balancing.

The forged steel crankshaft is fully balanced with eight counterweights and supported by five main bearings. A helical gear pressed in No. 3 counterweight drives twin contra-rotating balance shafts in the shaft housing within the lower crankcase.

Straight from the Toyota press room!!!

http://www.toyota.com/toyotaSearch/s...afts&locale=en

The 16-valve DOHC engine uses VVT-i. Undersquare, with a bore of 3.48 inches and a stroke of 3.78 inches, it displaces 2,362 cc or 144.1 ci and operates with a 9.8:1 compression ratio to produce 158 hp at 6,000 rpm and 162 lb-ft of torque at 4,000 rpm. Its horsepower and torque curves cross at about 5,200 rpm.

Features include enhanced bore circularity for reduced friction, a block reinforced for additional rigidity, new, lighter-weight pistons and new piston shape, with an optimized skirt for reduced friction. This engine also uses a balance shaft for vibration suppression, and oil jets to help piston cooling.

Finally, this engine's exhaust system is improved to provide lower backpressure for improved output.

The 2.4-liter engine transmits its power through the five-speed manual transmission, but is available with a five-speed automatic. This is an ECT that is light and compact, and that uses a highly efficient torque converter.

Please tell me where it says it balaneces anything?

#34

Originally Posted by bluesciontc

Straight from the Toyota press room!!!

http://www.toyota.com/toyotaSearch/s...afts&locale=en

The 16-valve DOHC engine uses VVT-i. Undersquare, with a bore of 3.48 inches and a stroke of 3.78 inches, it displaces 2,362 cc or 144.1 ci and operates with a 9.8:1 compression ratio to produce 158 hp at 6,000 rpm and 162 lb-ft of torque at 4,000 rpm. Its horsepower and torque curves cross at about 5,200 rpm.

http://www.toyota.com/toyotaSearch/s...afts&locale=en

The 16-valve DOHC engine uses VVT-i. Undersquare, with a bore of 3.48 inches and a stroke of 3.78 inches, it displaces 2,362 cc or 144.1 ci and operates with a 9.8:1 compression ratio to produce 158 hp at 6,000 rpm and 162 lb-ft of torque at 4,000 rpm. Its horsepower and torque curves cross at about 5,200 rpm.

#36

Yeah but it defeats any purpose. It's the formula for HP. Anyone who would even remotely be interested in this type of information would already know it.

Anyhow, this still has bee a very informative thread for those without a service manual.

Anyhow, this still has bee a very informative thread for those without a service manual.

#37

Yea i have the 05 service manual  I was able to find the double hex at a autozone of all places lol - even was able to get the head bolt out i damaged with a t55 - unforunately it sacraficed the 10mm bihex bit - i tap it into the damaged bolt with a mallet and now it wont come out of the bolt lol as for the balance shafts my bearings on mine looked about the same - utter destruction lol I cant wait to get my build done - just wish i didnt have to work all day so i could have more time on it lol

I was able to find the double hex at a autozone of all places lol - even was able to get the head bolt out i damaged with a t55 - unforunately it sacraficed the 10mm bihex bit - i tap it into the damaged bolt with a mallet and now it wont come out of the bolt lol as for the balance shafts my bearings on mine looked about the same - utter destruction lol I cant wait to get my build done - just wish i didnt have to work all day so i could have more time on it lol

Thread

Thread Starter

Forum

Replies

Last Post

SkillFreeJake

Scion tC 2G Aero & Exterior

17

07-27-2015 12:34 AM