Boosted XB dyno results

#41

Paul, at the risk of sounding offended by your condescension, DUH!

I'm not trying to understand why different turbo setups produce different results, I'm trying to better understand the complex interaction of the component variables so that I may apply this knowledge for my benefit and possibly other readers who don't already know everything.

Perhaps you can explain the marked difference between the 2 runs in sheet #1? Aside from different boost levels, I doubt they changed much else in between runs. What would cause a very flat tq curve to fall off so drastically after 5000rpm simply by raising the boost level? I'd like to know.

I'm not trying to understand why different turbo setups produce different results, I'm trying to better understand the complex interaction of the component variables so that I may apply this knowledge for my benefit and possibly other readers who don't already know everything.

Perhaps you can explain the marked difference between the 2 runs in sheet #1? Aside from different boost levels, I doubt they changed much else in between runs. What would cause a very flat tq curve to fall off so drastically after 5000rpm simply by raising the boost level? I'd like to know.

Unless you where standing right there the entire time, there could have been a number of scenarios that could have occurred to alter the power curves that much.

Here are just a few:

Owner could have had an exhaust leak that was not real bad at the WG set boost level, but got progressively worse as boost increased.

The owner could have disconnected the exhaust due to bad back pressure.

The tuner could have not had the spark and fuel delivery correct to compensate for the new boost level thus causing poor power response.

The turbine wheel could be small and have a small turbine A/R, so it begins to choke on the increased air flow at higher boost levels and makes peak torque quickly, but can not retain the power past that point.

The compressor wheel could be small and out of it's efficiency range or horribly mis-matched compressor to turbine arrangement (i.e.-large comp wheel with SMALL turbine wheel and A/R)

This is why I worded my previous post the way I did.

#42

My question would be if you wanted to see a flat tq curve what would you do to achive this...here is what you have

1. stock tc

2. dezod turbo kit with spec turbo (s1)

now what else would you add or change to get that flat curve?

(leaving out tune as part of the equation for now)

1. stock tc

2. dezod turbo kit with spec turbo (s1)

now what else would you add or change to get that flat curve?

(leaving out tune as part of the equation for now)

#43

My question would be if you wanted to see a flat tq curve what would you do to achive this...here is what you have

1. stock tc

2. dezod turbo kit with spec turbo (s1)

now what else would you add or change to get that flat curve?

(leaving out tune as part of the equation for now)

1. stock tc

2. dezod turbo kit with spec turbo (s1)

now what else would you add or change to get that flat curve?

(leaving out tune as part of the equation for now)

Now, also remember, a stock tC using a stock exhaust is very restrictive. So, if you want to flatten the TQ curve without sacrificing power, try a larger turbine A/R with some good tuning.

If you want a more free flowing exhaust, you can get that TQ curve pretty flat with a larger exhaust (3") and some tuning on a small turbine A/R. PTuning did this on one of our customers car on their dyno.

#45

Should I want the meanest TQ curve ever, I'd size the turbo a little different, but again, on a stock tC, I would like to try the S1 with a small comp wheel (54 or 50) with an .82 A/R turbine.

#46

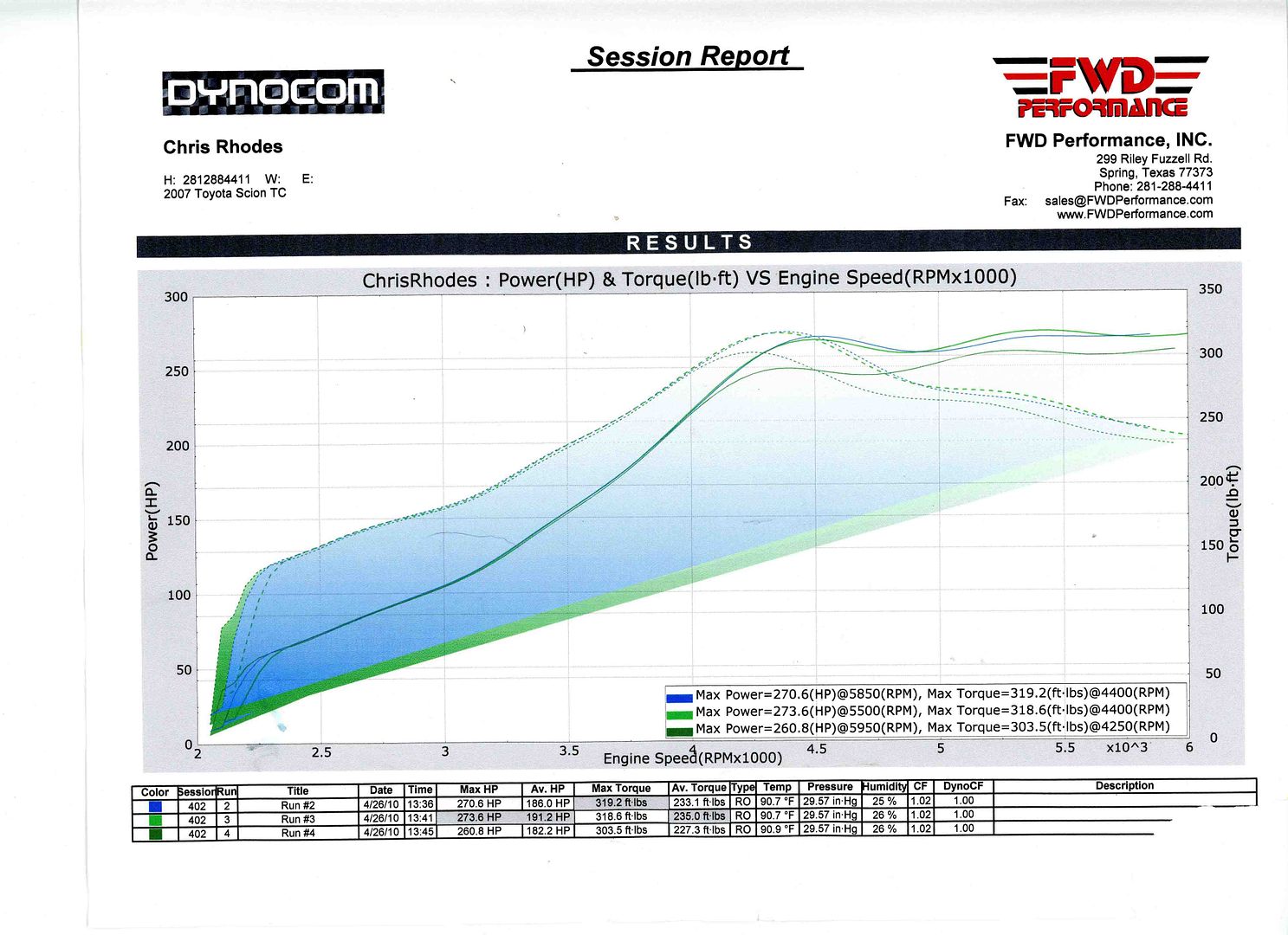

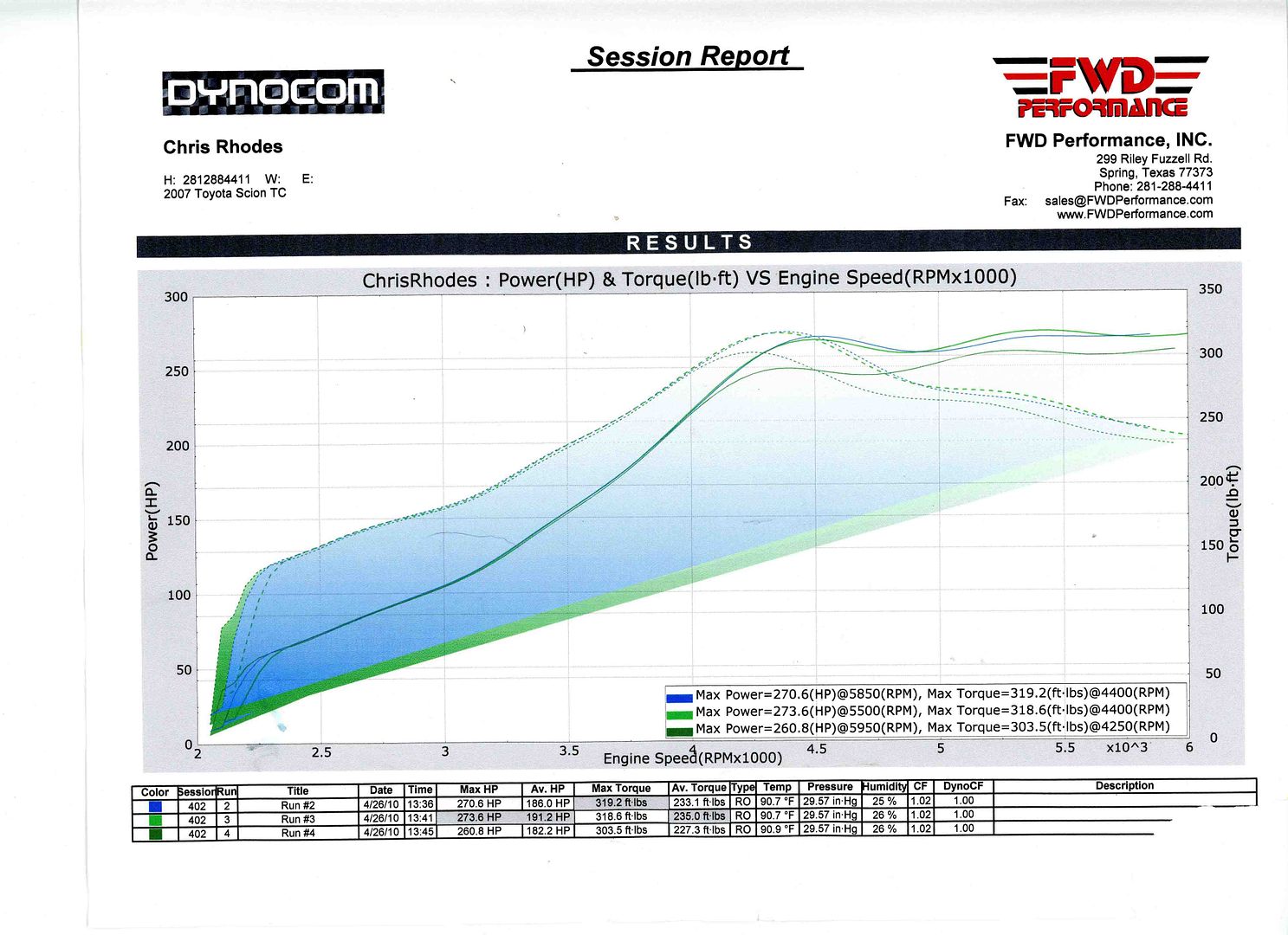

just an example

This is at 8-9psi on a t3/t4b .82 ar turbine housing, stage 5 turbine wheel, 3" downpipe necked down by s-pipe to 2.5" with exhaust cutout open (2.5"). 3 degrees of retard @ 8psi and tappers. afr was roughly (cant remember exactly) 11.4-11.7

what all would you change to this setup to net a flatter curve

This is at 8-9psi on a t3/t4b .82 ar turbine housing, stage 5 turbine wheel, 3" downpipe necked down by s-pipe to 2.5" with exhaust cutout open (2.5"). 3 degrees of retard @ 8psi and tappers. afr was roughly (cant remember exactly) 11.4-11.7

what all would you change to this setup to net a flatter curve

#47

Depends on my power goals. Personally, for power levels of 250-350 wheel, I would use the off the shelf S1 components with good tuning.

Should I want the meanest TQ curve ever, I'd size the turbo a little different, but again, on a stock tC, I would like to try the S1 with a small comp wheel (54 or 50) with an .82 A/R turbine.

Should I want the meanest TQ curve ever, I'd size the turbo a little different, but again, on a stock tC, I would like to try the S1 with a small comp wheel (54 or 50) with an .82 A/R turbine.

#48

I have a question about my dyno results. After looking at a lot of 2AZ dyno sheets I've noticed that the torque curve generally falls off after peaking between 4-5k rpm. Some fall off more than mine and others less but in a few cases I've seen really flat tq curves even at low boost (6-8psi). What are some of the factors that affect this? I can't believe that tuning alone can make such a dramatic difference. Can a small turbine housing affect the tq curve? What about the manifold? EL vs say cast iron? Exhaust restriction?

Just looking for ideas, TIA.

Just looking for ideas, TIA.

just an example

This is at 8-9psi on a t3/t4b .82 ar turbine housing, stage 5 turbine wheel, 3" downpipe necked down by s-pipe to 2.5" with exhaust cutout open (2.5"). 3 degrees of retard @ 8psi and tappers. afr was roughly (cant remember exactly) 11.4-11.7

what all would you change to this setup to net a flatter curve

This is at 8-9psi on a t3/t4b .82 ar turbine housing, stage 5 turbine wheel, 3" downpipe necked down by s-pipe to 2.5" with exhaust cutout open (2.5"). 3 degrees of retard @ 8psi and tappers. afr was roughly (cant remember exactly) 11.4-11.7

what all would you change to this setup to net a flatter curve

Edit: interestingly as well if you put your timing numbers into a 2d line on a graph it would look like a mirror image of your torque curve ;)

I have to say as well these comments are assuming you are using the correct turbocharger for your application, mainly nothing too small. If you use a small compressor on an engine that is too large it will have to spin much faster and out of it's efficiency range, creating nothing more than a lot of hot compressed air, and the hotter the IAT the less dense the air and less torque you will make.

#50

Your timing map will directly influence your torque curve.

After you hit peak torque (initial boost spike), safely add the timing back in and adjust fuel where necessary. If you want a flat torque curve and everything mechanically is sound all you need to do is construct it.

After you hit peak torque (initial boost spike), safely add the timing back in and adjust fuel where necessary. If you want a flat torque curve and everything mechanically is sound all you need to do is construct it.

#52

Timing. Your lowest timing numbers will be found at the highest load point which will correspond as your peak torque. This is where the highest cylinder pressure is found and this is where the lowest timing is needed to prevent detonation. Timing has a profound effect on AFR. You cannot have one without the other. Meaning if you change one you MUST change the other. It is a delicate balance. So, if you want a flatter torque curve adjust your timing. If your lowest timing numbers are found at peak torque (which is also the most efficient time in the engines rpm band) then you don't need a flat timing number after that, you should be adding timing after the peak torque is made. This compensates for lack of volumetric efficiency. Remember, once you change that timing you need to change the fuel delivery to maintain a steady AFR.

#53

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

My comment was not intended to be condescending at all. It was merely pointing out that the entire setup needs to be taken into account to thoroughly understand why the dynamics of the power delivery changed.

Unless you where standing right there the entire time, there could have been a number of scenarios that could have occurred to alter the power curves that much.

Here are just a few:

Owner could have had an exhaust leak that was not real bad at the WG set boost level, but got progressively worse as boost increased.

The owner could have disconnected the exhaust due to bad back pressure.

The tuner could have not had the spark and fuel delivery correct to compensate for the new boost level thus causing poor power response.

The turbine wheel could be small and have a small turbine A/R, so it begins to choke on the increased air flow at higher boost levels and makes peak torque quickly, but can not retain the power past that point.

The compressor wheel could be small and out of it's efficiency range or horribly mis-matched compressor to turbine arrangement (i.e.-large comp wheel with SMALL turbine wheel and A/R)

This is why I worded my previous post the way I did.

Unless you where standing right there the entire time, there could have been a number of scenarios that could have occurred to alter the power curves that much.

Here are just a few:

Owner could have had an exhaust leak that was not real bad at the WG set boost level, but got progressively worse as boost increased.

The owner could have disconnected the exhaust due to bad back pressure.

The tuner could have not had the spark and fuel delivery correct to compensate for the new boost level thus causing poor power response.

The turbine wheel could be small and have a small turbine A/R, so it begins to choke on the increased air flow at higher boost levels and makes peak torque quickly, but can not retain the power past that point.

The compressor wheel could be small and out of it's efficiency range or horribly mis-matched compressor to turbine arrangement (i.e.-large comp wheel with SMALL turbine wheel and A/R)

This is why I worded my previous post the way I did.

I wasn't asking about a tree, I was asking about how different trees affect the forest. Anyway, I may not have been clear enough since Crush has been able to get some relevant answers to the same question.

#54

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Timing. I'd say that Shawn Chruch is probably a little more adept at tuning than the average joe.

Timing. Your lowest timing numbers will be found at the highest load point which will correspond as your peak torque. This is where the highest cylinder pressure is found and this is where the lowest timing is needed to prevent detonation. Timing has a profound effect on AFR. You cannot have one without the other. Meaning if you change one you MUST change the other. It is a delicate balance. So, if you want a flatter torque curve adjust your timing. If your lowest timing numbers are found at peak torque (which is also the most efficient time in the engines rpm band) then you don't need a flat timing number after that, you should be adding timing after the peak torque is made. This compensates for lack of volumetric efficiency. Remember, once you change that timing you need to change the fuel delivery to maintain a steady AFR.

Edit: interestingly as well if you put your timing numbers into a 2d line on a graph it would look like a mirror image of your torque curve ;)

I have to say as well these comments are assuming you are using the correct turbocharger for your application, mainly nothing too small. If you use a small compressor on an engine that is too large it will have to spin much faster and out of it's efficiency range, creating nothing more than a lot of hot compressed air, and the hotter the IAT the less dense the air and less torque you will make.

Timing. Your lowest timing numbers will be found at the highest load point which will correspond as your peak torque. This is where the highest cylinder pressure is found and this is where the lowest timing is needed to prevent detonation. Timing has a profound effect on AFR. You cannot have one without the other. Meaning if you change one you MUST change the other. It is a delicate balance. So, if you want a flatter torque curve adjust your timing. If your lowest timing numbers are found at peak torque (which is also the most efficient time in the engines rpm band) then you don't need a flat timing number after that, you should be adding timing after the peak torque is made. This compensates for lack of volumetric efficiency. Remember, once you change that timing you need to change the fuel delivery to maintain a steady AFR.

Edit: interestingly as well if you put your timing numbers into a 2d line on a graph it would look like a mirror image of your torque curve ;)

I have to say as well these comments are assuming you are using the correct turbocharger for your application, mainly nothing too small. If you use a small compressor on an engine that is too large it will have to spin much faster and out of it's efficiency range, creating nothing more than a lot of hot compressed air, and the hotter the IAT the less dense the air and less torque you will make.

Thank you Don. This is the kind of info I was asking for.

Since I don't see any likely hardware causes for the Tq curve fall-off after 4000rpm, I think I'll get re-tested under better conditions and see how much the results change. IMO a dyno test performed at 85F ambient, 205F + ECT and 120F+ IAT with no airflow to the IC or intake is not very representative of real-world conditions. In the real world at 85F ambient, ECT would have been <200F and IAT would have been <100F with ~100mph wind thru the IC and towards the intake instead of no airflow. I'm pretty sure that ECU "guardian" protection had kicked in at 120F+ IAT and retarded ign timing. We'll see...

.

.

.

Last edited by ScionFred; 10-31-2010 at 06:06 AM.

#55

Intentional or not, it came across that way. Especially the part about not being able to see the forest for the trees. In case you missed it, I specifically chose those dyno sheets because they were from the same dyno, same engine, same turbo kit, same turbo and tuned by the same shop. These results are not just some random user-posted dyno sheets. They were all posted by Rob of Descendant Racing to showcase their ver. 2 turbo kit.

I wasn't asking about a tree, I was asking about how different trees affect the forest. Anyway, I may not have been clear enough since Crush has been able to get some relevant answers to the same question.

I wasn't asking about a tree, I was asking about how different trees affect the forest. Anyway, I may not have been clear enough since Crush has been able to get some relevant answers to the same question.

From the thread:

Here are the long awaited DESCENDANT Intake manifold results as promised.

First sheet below is dated and belongs to a local customer that came to WORLD Racing originally looking for the DESCENDANT Turbo Kit...an older gentlemen who wanted more passing power in his Scion but nothing flashy. So...first goes DESCENDANT Turbo Kit @ 8-9psi with TRD exhaust:

After a few months go by (look at the dated dyno chart) customer comes back looking for more power but wants his daily driver to remain stealth. So, we add intake manifold & fuel rail and gave it a shot. Below are he’s next dyno numbers...these pulls are his second dyno attempt with the DESCENDANT Turbo Kit at 8-9psi, the TRD exhaust & now the intake manifold & fuel rail. Plus TRD Clutch & LSD.

First sheet below is dated and belongs to a local customer that came to WORLD Racing originally looking for the DESCENDANT Turbo Kit...an older gentlemen who wanted more passing power in his Scion but nothing flashy. So...first goes DESCENDANT Turbo Kit @ 8-9psi with TRD exhaust:

After a few months go by (look at the dated dyno chart) customer comes back looking for more power but wants his daily driver to remain stealth. So, we add intake manifold & fuel rail and gave it a shot. Below are he’s next dyno numbers...these pulls are his second dyno attempt with the DESCENDANT Turbo Kit at 8-9psi, the TRD exhaust & now the intake manifold & fuel rail. Plus TRD Clutch & LSD.

The addition of the intake manifold drastically alters the internal air flow properties of the air and volume that enters the combustion chambers per gulp of the engine. Therefore, you can not alter air flow without altering timing and fuel flow. With these other variables modified as well, the engine becomes more efficient making more power (assuming all else is stable and mechanically sound)

I am not trying to pick a fight here Brett. Just stating the facts and attempting to keep things in light of truth and facts with being on topic.

How is that setup of yours running?

Last edited by paul_dezod; 11-01-2010 at 04:21 PM.

#57

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Rob posted up that the reasons why there where differences in the kit results from that thread. There was addition of their intake manifold, which changed the entire combustion equation Brett.

Regardless of how my comment came across, I still stand corrected and my comment was appropriate and not condescending in that fact that the turbo system and all of it's components must be viewed in a larger picture. Each and every component changes or alters the grand scheme. (simply put Brett)

The addition of the intake manifold drastically alters the internal air flow properties of the air and volume that enters the combustion chambers per gulp of the engine. Therefore, you can not alter air flow without altering timing and fuel flow. With these other variables modified as well, the engine becomes more efficient making more power (assuming all else is stable and mechanically sound)

I am not trying to pick a fight here Brett. Just stating the facts and attempting to keep things in light of truth and facts with being on topic.

How is that setup of yours running?

Regardless of how my comment came across, I still stand corrected and my comment was appropriate and not condescending in that fact that the turbo system and all of it's components must be viewed in a larger picture. Each and every component changes or alters the grand scheme. (simply put Brett)

The addition of the intake manifold drastically alters the internal air flow properties of the air and volume that enters the combustion chambers per gulp of the engine. Therefore, you can not alter air flow without altering timing and fuel flow. With these other variables modified as well, the engine becomes more efficient making more power (assuming all else is stable and mechanically sound)

I am not trying to pick a fight here Brett. Just stating the facts and attempting to keep things in light of truth and facts with being on topic.

How is that setup of yours running?

Anyway, whatever offense I took to your previous reply is forgotten. I have some very definite ideas about how to flatten my heat-soaked dyno test tq curve but won't be able to test them for a while. Until then the only thing that could make me happier with my current setup would be more power but then that would most likely make my AT fail and make me sad. So all things considered, I've acheived all of my goals except budget.

#59

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Thanks Paul. It's not the setup most people would want since it's limited to about 260BHP but it's working well for a DD on stock AT.

FWIW, I recently confirmed that there is a TSB for my main wiring harness. Although I have not experienced any of the symptoms for the TSB it makes me wonder if theses known problems with the oem harness might have played a role in some of the harness-related issues that I've had with the FIC and X1. If some of the sensor signals were weak to start, the addtion of extra connections and wire length could have further weakened those signals and caused some of the problems I encountered.

FWIW, I recently confirmed that there is a TSB for my main wiring harness. Although I have not experienced any of the symptoms for the TSB it makes me wonder if theses known problems with the oem harness might have played a role in some of the harness-related issues that I've had with the FIC and X1. If some of the sensor signals were weak to start, the addtion of extra connections and wire length could have further weakened those signals and caused some of the problems I encountered.

#60

Thanks Paul. It's not the setup most people would want since it's limited to about 260BHP but it's working well for a DD on stock AT.

FWIW, I recently confirmed that there is a TSB for my main wiring harness. Although I have not experienced any of the symptoms for the TSB it makes me wonder if theses known problems with the oem harness might have played a role in some of the harness-related issues that I've had with the FIC and X1. If some of the sensor signals were weak to start, the addtion of extra connections and wire length could have further weakened those signals and caused some of the problems I encountered.

FWIW, I recently confirmed that there is a TSB for my main wiring harness. Although I have not experienced any of the symptoms for the TSB it makes me wonder if theses known problems with the oem harness might have played a role in some of the harness-related issues that I've had with the FIC and X1. If some of the sensor signals were weak to start, the addtion of extra connections and wire length could have further weakened those signals and caused some of the problems I encountered.