WR Race Intake Manifold for 2nd Gen XB.

#23

Originally Posted by ShaffNasty

I read on the tC thread that this is a bust... i guess you need fuel management contorler like AEM for it to properly work... From what they said it sounds like it brings in too buch air and makes the car run really lean... maybe some bigger injectors would help...

https://www.scionlife.com/forums/vie...=asc&&start=80

https://www.scionlife.com/forums/vie...=asc&&start=80

#28

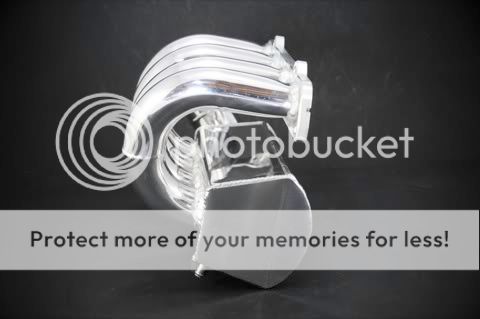

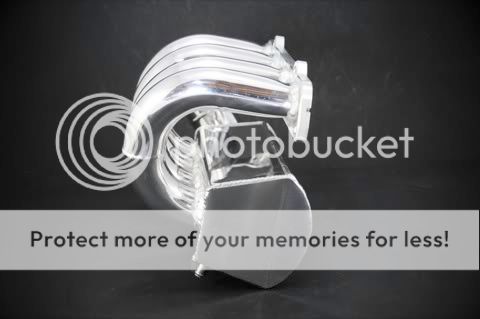

PICTURES OF THE NEW VERSION... ( PRODUCTION PIECE )

NEW FEATURES:

1. NEW PLENUM SHAPE BETTER FLOW AND FITMENT

2. LONGER RUNNERS FOR MORE TORQUE AND LOW-TOPEND RANGE POWER

3. LARGER VELOCITY STACKS FOR HIGHER FLOW

4. ALL AIR NIPPLES ( SAME AMOUNT & SIZE AS STOCK )

5. TIG WELDED TO HOLD UP TO 35LBS.

6. PLENUM IS MADE OF 4MM THICK ALUMINUM

7. BRACKET FROM TB TO HEAD FLANGE TO ELIMINATE STRESS CRACKING FROM VIBRATION

8. GOOD FOR NA AND FI SETUP'S.

The VELOCITY STACKS that we use inside the Intake manifolds..

NEW FEATURES:

1. NEW PLENUM SHAPE BETTER FLOW AND FITMENT

2. LONGER RUNNERS FOR MORE TORQUE AND LOW-TOPEND RANGE POWER

3. LARGER VELOCITY STACKS FOR HIGHER FLOW

4. ALL AIR NIPPLES ( SAME AMOUNT & SIZE AS STOCK )

5. TIG WELDED TO HOLD UP TO 35LBS.

6. PLENUM IS MADE OF 4MM THICK ALUMINUM

7. BRACKET FROM TB TO HEAD FLANGE TO ELIMINATE STRESS CRACKING FROM VIBRATION

8. GOOD FOR NA AND FI SETUP'S.

The VELOCITY STACKS that we use inside the Intake manifolds..

#29

damn!!!! that bad boy looks effen sweet!!! so if im just running cold air intake and header/ s-pipe combo and i throw in one of these bad boys, what kind of an increase in hp & tq should i be expecting?? Oh, and whats the price, can we order now?

#31

Originally Posted by drewsxb808

damn!!!! that bad boy looks effen sweet!!! so if im just running cold air intake and header/ s-pipe combo and i throw in one of these bad boys, what kind of an increase in hp & tq should i be expecting?? Oh, and whats the price, can we order now?

then he calls back 2 days later and said he was changin his oil.. WTF????

#32

JUST FYI.. This was taken from ENGINEBUILDERMAG.COM

Runner Length:

Runner length also affects the rpm range where an engine makes the most power. Longer runner lengths have a “ram” effect that helps keep the air moving forward as the intake valves open and shut. When an intake valve opens, there is a short lag before the cylinder starts to pull air through the runner into the combustion chamber. A longer runner helps maintain the inertia of the air column so it will fill the cylinder faster.

When the intake valve slams shuts, the momentum of the incoming air hits a roadblock, and a pressure wave rushes backwards through the intake port and runner. A longer intake runner tends to keep the air moving in the right direction in spite of the reversionary pressure pulse that is trying to push it backwards.

Shorter runners, on the other hand, usually flow better at higher engine rpm. Reducing the length of the runners may allow the engine to make more power at the top end, but the trade-off may be a loss of power and torque at lower speeds. When choosing an intake manifold, therefore, the runner length should match the engine rpm range where the engine is built to make the most power. If you are building a low rpm torque motor, you want an intake manifold with longer high velocity runners. On the other hand, if you are building a high revving motor, you will probably want a manifold with shorter runners or runners with a larger cross-sectional area to flow more air.

Link to this article..

http://www.enginebuildermag.com/Arti...d_to_wild.aspx

Runner Length:

Runner length also affects the rpm range where an engine makes the most power. Longer runner lengths have a “ram” effect that helps keep the air moving forward as the intake valves open and shut. When an intake valve opens, there is a short lag before the cylinder starts to pull air through the runner into the combustion chamber. A longer runner helps maintain the inertia of the air column so it will fill the cylinder faster.

When the intake valve slams shuts, the momentum of the incoming air hits a roadblock, and a pressure wave rushes backwards through the intake port and runner. A longer intake runner tends to keep the air moving in the right direction in spite of the reversionary pressure pulse that is trying to push it backwards.

Shorter runners, on the other hand, usually flow better at higher engine rpm. Reducing the length of the runners may allow the engine to make more power at the top end, but the trade-off may be a loss of power and torque at lower speeds. When choosing an intake manifold, therefore, the runner length should match the engine rpm range where the engine is built to make the most power. If you are building a low rpm torque motor, you want an intake manifold with longer high velocity runners. On the other hand, if you are building a high revving motor, you will probably want a manifold with shorter runners or runners with a larger cross-sectional area to flow more air.

Link to this article..

http://www.enginebuildermag.com/Arti...d_to_wild.aspx

#34

Originally Posted by Beckenbauer

ok so us NA's wouldnt need management to run this properly???