Check your thread engagement!

#21

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

#22

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Thanks. I tried Gorilla SD-ET tuner lugs but they don't make SD-ET locks to match them! I don't really trust splined tuner lugs alone for theft deterrence since all anyone needs is the standard Gorilla key to remove them. It sux that the selection of ET lug nuts is so limited.

#23

Thanks. I tried Gorilla SD-ET tuner lugs but they don't make SD-ET locks to match them! I don't really trust splined tuner lugs alone for theft deterrence since all anyone needs is the standard Gorilla key to remove them. It sux that the selection of ET lug nuts is so limited.

Here is a link to the McGard wheel locks- http://www.summitracing.com/parts/MCG-25357

#24

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

I used the gorilla SD-ET tuner lugs along with 1 McGard wheel lock per wheel. I havent had any issues with that, is there something I am missing about using those with the gorilla lugs?

Here is a link to the McGard wheel locks- http://www.summitracing.com/parts/MCG-25357

Here is a link to the McGard wheel locks- http://www.summitracing.com/parts/MCG-25357

BTW, it seems as though your wheel mounting pad is the same thickness as mine and ET nuts are required. Good choice.

#25

Not really, I just need to use ET nuts and haven't found any SD-ET tuner locks. If you're getting 8.5 turns on the SD-ET lugs, that would mean ~6.5 turns on the non-ET McGard locks. It's probably fine but the thread engagement on your locks is sub-optimal.

BTW, it seems as though your wheel mounting pad is the same thickness as mine and ET nuts are required. Good choice.

BTW, it seems as though your wheel mounting pad is the same thickness as mine and ET nuts are required. Good choice.

#26

#27

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

The guy I ordered my new lugs from commented that he's seen cases where the shank on the Gorilla ET lugs don't fit properly in some aftermarket wheels. AFAIK the proper wheel stud hole dia. for a ET lug nut is .625" so the .620" Gorilla shank should fit. I measured my Gorilla lugs and my Tire Rack shanks and sure enough the .620" dia Gorilla shank is a hair bigger than the .620" Tire Rack shank. Possibly due to the triple-chrome plating vs the thin zinc plating. Gorilla should have considered that in their design but maybe they didn't. I'll ream my wheels out a little if I have to.

How can something as simple as lug nuts get so complicated?

scion619: Happy to be of help.

#28

That's good news. Just make sure that your ET lug shanks are fully seating in the wheel then because the 7mm shank should provide an extra ~4 turns of engagement. If McGard = ~8 turns, your SD-ET should = ~12 turns. It's important that the shank extends through the wheel far enough that the lug seat makes good contact with the wheel seat.

The guy I ordered my new lugs from commented that he's seen cases where the shank on the Gorilla ET lugs don't fit properly in some aftermarket wheels. AFAIK the proper wheel stud hole dia. for a ET lug nut is .625" so the .620" Gorilla shank should fit. I measured my Gorilla lugs and my Tire Rack shanks and sure enough the .620" dia Gorilla shank is a hair bigger than the .620" Tire Rack shank. Possibly due to the triple-chrome plating vs the thin zinc plating. Gorilla should have considered that in their design but maybe they didn't. I'll ream my wheels out a little if I have to.

How can something as simple as lug nuts get so complicated?

scion619: Happy to be of help.

The guy I ordered my new lugs from commented that he's seen cases where the shank on the Gorilla ET lugs don't fit properly in some aftermarket wheels. AFAIK the proper wheel stud hole dia. for a ET lug nut is .625" so the .620" Gorilla shank should fit. I measured my Gorilla lugs and my Tire Rack shanks and sure enough the .620" dia Gorilla shank is a hair bigger than the .620" Tire Rack shank. Possibly due to the triple-chrome plating vs the thin zinc plating. Gorilla should have considered that in their design but maybe they didn't. I'll ream my wheels out a little if I have to.

How can something as simple as lug nuts get so complicated?

scion619: Happy to be of help.

#29

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

#31

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Yup, that definitely explains it. It also makes me wonder how much TE other folks are getting with their cast wheels. 6.5 turns (~10mm) might be enough but I'm not willing to risk it.

#32

Im glad to know that I am getting enough thread engagement. Thanks. Although I never would worried about that if you didnt start this thread, lol.

#33

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

A week ago I knew next to nothing about lug nuts but when Tire Rack sent me these funny looking zinc-plated ET/Ultra shank lug nuts it forced me to learn about them so I could find suitable replacements. I suppose I have to give them credit for taking individual vehicle stud length and wheel mounting pad thickness into account for every set of wheels they sell even if they sent me cheesy zinc lug nuts that are totally unsuitable for exposed use.

#34

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Here is a great read on ET lug nuts:

http://wheelprofessor.com/2009/02/20...-they-and-why/

One addtional thought is that the extra 6mm of thread engagement offered by ET/Ultra style lug nuts is an easy way to add 5mm wheel spacers without needing longer studs. Unfortunately you're currently limited to only a few styles and one color (silver chrome) when choosing ET lug nuts.

http://wheelprofessor.com/2009/02/20...-they-and-why/

"In my opinion, ET lug nuts should be used on all aluminum wheels. In summary, what does an ET Type lug nut do? It provides a method to assure proper thread engagement. What is proper thread engagement? Proper thread engagement is defined as engaging the threads onto the bolt or stud by at least the diameter of the bolt or stud."

#36

Just removed a rear from my Eclipse with the standard bolt lugs and they were solid. I've switched wheels a couple times now on the xB2 and each time the lug nuts were also solid. I'm not sure how serious an issue this is, however, doesn't hurt to be aware  !

!

!

!

#37

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

I think insufficient lug nut thread engagement is one of those potentially catastrophic risks that rarely results in the worst case scenerio (a wheel coming off at high speed). I'm sure there are lots of people running around like this with aftermarket wheels and maybe one in a hundred loses a few lug nuts and one in a thousand loses a wheel and one in a million is killed in the ensuing crash. If I didn't know about it, it wouldn't worry me and I'd probably never have a problem with 10mm of TE instead of the 12mm recommended by everyone.

Bottom line for me is this:

1) The XB2 has short wheel studs.

2) Aftermarket wheels have mounting pads with different thicknesses.

3) It's well worth the time to remove a single lug nut and then count how many turns it makes until it seats. 8 full turns = safe

Bottom line for me is this:

1) The XB2 has short wheel studs.

2) Aftermarket wheels have mounting pads with different thicknesses.

3) It's well worth the time to remove a single lug nut and then count how many turns it makes until it seats. 8 full turns = safe

#38

Thread Starter

Joined: Jun 2007

Posts: 3,387

From: Baltimore, MD, USA

Just an update to the ET/Ultra lug nut discussion. I received and installed my Gorilla ET/Ultra lock lug nuts a few days ago and immediately noticed that my wheel imbalance was gone. With Gorilla std conical seat lug nuts my wheels felt out of balance above 65mph but not anymore.

As for loosening lug nuts, I re-torqued the std conical seat lugs with 10mm thread engagement after a few hundred miles and none of them were loose. I did the same with the 14mm thread engagement ET lug nuts and none of them were loose. Definitive? hardly...

Hubcentric + lugcentric FTMFW!

BTW, I highly recommend that anyone using aftermarket wheels with hubcentric rings torque their lug nuts with the wheels raised. Regardless of how tight those hub rings may seem there is still enough play to potentially cause unwanted centering/balance issues if torqued tight with the vehicle weight on them.

As for loosening lug nuts, I re-torqued the std conical seat lugs with 10mm thread engagement after a few hundred miles and none of them were loose. I did the same with the 14mm thread engagement ET lug nuts and none of them were loose. Definitive? hardly...

Hubcentric + lugcentric FTMFW!

BTW, I highly recommend that anyone using aftermarket wheels with hubcentric rings torque their lug nuts with the wheels raised. Regardless of how tight those hub rings may seem there is still enough play to potentially cause unwanted centering/balance issues if torqued tight with the vehicle weight on them.

#40

I know this is an older thread, but enjoyed reading it and thought it worthy of a bump...with a question, of course!

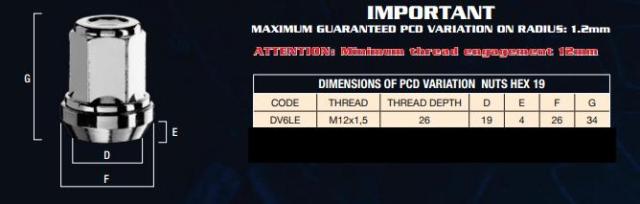

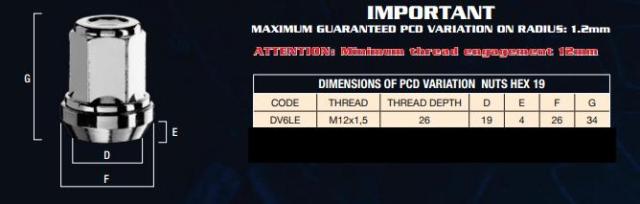

I'm looking into getting these PCD Variation lug nuts:

Closed Nut, Hex19 M12x1,5x34 Zinc.Pl.12M

So all I would need to do is figure out the mounting pad depth and use the 34mm height to calculate if I will have enough thread engagement?

Here's a pic of the dimensions:

I'm looking into getting these PCD Variation lug nuts:

Closed Nut, Hex19 M12x1,5x34 Zinc.Pl.12M

So all I would need to do is figure out the mounting pad depth and use the 34mm height to calculate if I will have enough thread engagement?

Here's a pic of the dimensions: